While cleaning recently, I came across one of my team projects from Uni and thought that I might go through and explain what it is and what it does.

The project was centred around Polysomnography, which is the measurement of several physiological signals a person generates while sleeping. A doctor then uses the recorded information as a tool to diagnose any problems the patient may have, such as sleep apnoea.

Our assignment was to design and build the simplified prototype system in the image below. It's able to measure breathing rate, heart rate, snoring sounds, and throat vibrations, and then combine the signals so they can be transmitted over a single data cable.

One thing to note is that about 95% of all of the parts for this build were sourced from Dick Smith Electronics, back when they actually sold electronics. I think now I'd be lucky to find any parts there, maybe some cable ties.

|

| Polysomnography Project |

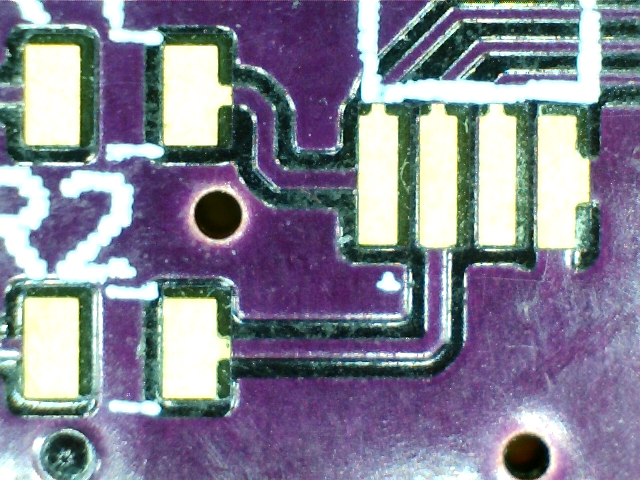

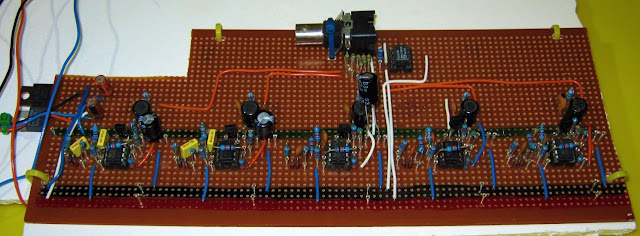

Frequency division multiplexing (FDM) was used to transmit all of the data over a single cable. The five similar sub-circuits at the bottom of the image below contain an oscillator and a mixer. The oscillator generates a carrier signal, while the mixer modulates the carrier with a signal from one of the sensors that are powered by the FDM board. An op-amp summing circuit then combines the modulated carriers into one signal. Some parts have not been soldered to the board, instead they are connected via round header pins. This allows specific parameters such as oscillation frequency to be changed.

|

| Frequency Division Multiplexing Board |

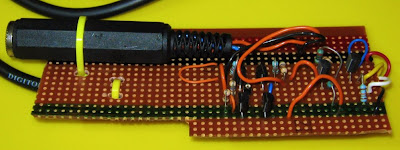

The next board is nothing spectacular. It's just a pre-amplifier for the microphone that is used to record snoring sounds.

|

| Microphone Pre-amplifier Board |

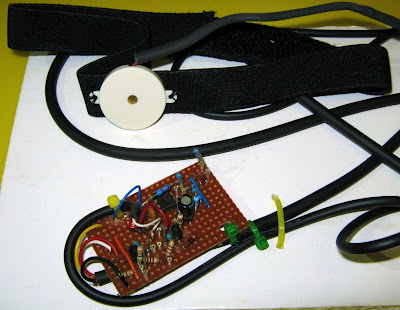

The next board is almost the same as the last, it's just a pre-amplifier for a piezo electric sensor used to detect throat vibration. The sensor is held in place against the throat using a velcro strap. A slight choking hazard but this was only a prototype.

|

| Throat Vibration Sensor |

A face mask from an asthma machine was used to make a breathing sensor. The mask was slightly altered to make sure all the air flowed past a thermistor when breathing in and out. As the air passing the sensor is hotter when a person is breathing out you can easily see the breathing pattern of the patient. A simple circuit was then used to convert the resistance of the thermistor to a voltage.

The initial result wasn't spectacular due to the thermal response of the thermistor. To improve the performance the outer coating of the thermistor was sanded off to make it more responsive. Probably not the safest move, but you do what you can with what you've got.

|

| Breathing Sensor |

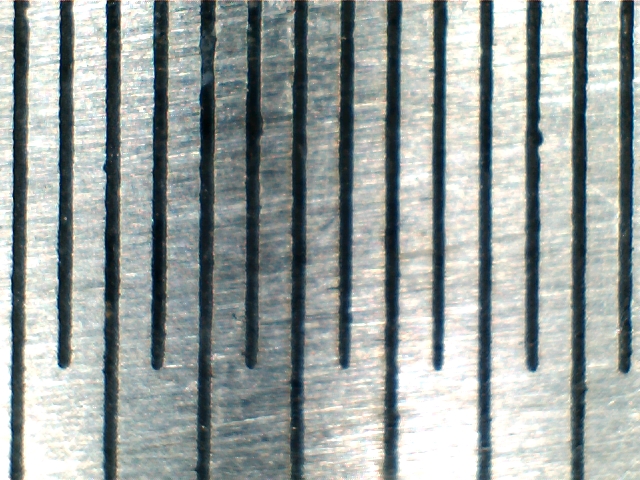

The ECG board uses an instrumentation amplifier to improve common mode rejection while sensing the hearts electrical impulse. A last minute change required a hacked up daughter board containing the instrumentation amplifier to be inserted into the socket of the old IC. After the instrumentation amplifier a couple stages of filtering and amplification. Finally and most importantly is an optical isolation stage. This stage is needed for safety. Because the probes of the ECG are connected to a patient, direct paths to main power need to be eliminated. By powering the amplification stage from a battery and isolating it from the main board, the risk of shocking the patient is significantly reduced.

|

| ECG board |

These are the ECG leads that were built. They were the most professional looking part of the project. Some audio cable, alligator clips, RCA plugs and a bit of heatshrink and you can do wonders. The alligator clips can clip onto the snaps on the back of ECG pads, however, in the product demonstration the alligator clips were attached to dollar coins and taped to the skin. Strategically shaving small areas makes removing the tape a lot easier.

|

| DIY Test Leads |

The most interesting thing about this project was how it made technology that seemed so complicated accessible. An ECG machine seems like something that would cost thousands of dollars to build, and it does if you want something good, but with a few basic parts you can hack something together for under 50 bucks.

Another interesting thing I learned from this project that's unique to this situation is that you can't hold your cards close to you chest when wearing a heart monitor. When doing a demonstration in front of your professor and he can see that your heart rate is 120 bpm, he has a fair idea you're terrified.