Lately I've been experimenting with surface mount components, trying to better understand how to design for them, how to solder them, and how to place them. I'm getting better at designing for them and understanding the different soldering methods, but I still have issues placing parts on PCBs. Using tweezers is okay, but I wanted to see if I got better results using a vacuum pick-up tool. After all, industrial pick and place machines use a vacuum to lift components, why can't I. So with that in mind, I decided to build my own, hopefully learning the idiosyncrasies of the process during the build.

| Home made vacuum pick-up tool |

My design was reasonably basic with only a few requirements. The vacuum pump needed to be controlled by foot, freeing up my hands to place parts. Ideally the hand-piece should be about the same size as a pen to make it ergonomic to use. Finally the hand-piece should be fitted with a luer-lock connector to allow tips to be easily changed. The rest of the design wasn't too important and was dictated mainly by what parts I could get my hands on. After an initial failed attempt I'm happy with the results, both aesthetically and functionally.

| Hand-piece with power supply, foot switch, and vacuum pump |

The Build

A couple items necessary for the build were a foot switch and a vacuum pump. The easiest way to get these was to order them through Little Bird Electronics.

The foot switch was sourced from Seeed Studios and would easily do the job. It's rated for 10 A at 250 V and has NC/NO contacts. The colour coded wires on my switch were wrong, so it pays to double check the wiring with a multi-meter first.

|

| Foot Switch - Image from seeed studio |

The vacuum pump was sourced from SparkFun Electronics and is capable of a vacuum of 16 inches of mercury which is about half an atmosphere. Ideally if there aren't any leaks the flow rate shouldn't matter as there will be almost no air flowing when parts are attached to the tool. The pump requires a 12 V, 1 A power source which is supplied by a switch mode wall-wart that was surplus from another project.

Half an atmosphere is more than enough to lift surface mount components. In a perfect demonstration of the Square cube law,

as the parts being lifted shrink, their mass shrinks by the cube of the

scaling factor, while the area available for lifting shrinks by only

the square of the scaling factor. For example, if the dimensions of a part are halved, it now weighs an eighth as much and has a quarter of the area to lift it. This means that ideally you would only need half the vacuum pressure to lift it. This means the vacuum pressure to lift components decreases as the parts get smaller.

|

| Vacuum Pump - Image from sparkfun.com used under a CC BY-NC-SA 3.0 license |

A simple cable harness was built to connect the foot switch, power supply, and vacuum pump.

With the main components sorted, all that was left was the hand piece. After thinking it over for a while I decided to use brass. It should be strong, but easy enough to work with and join. It did require me to buy a MAPP blow torch to silver solder all the parts together, but you can never have too many tools. I also had a fun couple of days figuring out how to solder, only burnt myself once too.

I didn't have access to a lathe or a suitable size of brass tubing, so I had to work with what I could find. I came across the injection moulded brass body piece shown below on ebay. I have no idea what it does or what it's for, but it was something I could work with. I started by cutting the pipe to length by removing the thread on the end.

|

| Brass body |

| Brass body without thread |

The barbed fitting on the end of the pipe was too large for the 1/4 inch ID tubing I had to fit the vacuum pump. This meant that another fitting needed to be added to the pipe to connect to the smaller tubing. The thread was cut off a barbed fitting similar to the one below and the barb soldered to the body of the hand-piece.

| Barbed fiting |

| The barbed fitting soldered to the main body |

In the close up of the soldered joint below you can see that it's a bit messy. Silver solder apparently works best when joining two closely fitting metal pieces, it isn't ideal for filling. I think If I had another go I could do a better job, but after a clean it'll look fine.

| The soldered joint |

The next step was quite nerve racking. Up until now the parts used were cheap and easily replaceable, the next part wasn't. The tiny luer lock connector to be fitted to the tip of the hand-piece cost forty dollars (you can get them cheaper overseas, everything costs more in Australia), and because I'd melted some test pieces when practising soldering I was a little hesitant.

| Luer lock connector to hold vacuum tips |

| Bevelled fittings before soldering |

I bit the bullet and soldered the luer connector to the main body and everything turned out perfectly. The solder was sucked into the joint and ran all the way around to make a beautiful joint. After a little filing you can see the result below. The grip on the luer connector was also sanded off to make the tool more comfortable to use.

Although the hand piece will accept any luer fitting, it's preferable to use a metal one. If a plastic fitting was used, the air flow through the tip could cause a static charge to build up on the plastic and discharge into the part being lifted damaging it. If a metal fitting is used, static build-up can be controlled.

Now for some tests.

| Metal Tip fitted to the hand-piece |

| Vacuum tip lifting an MSOP-8 package |

I know I said metal tips were preferred, but I have a set of plastic ones that I'm using to understand what size tip is needed to lift what package.

| 21 gauge blunt tip bent needle fitted |

| 22 gauge vacuum tip lifting an 0603 resistor (1.6 x 0.8 mm) |

The rubber suction cup in the images below was from a cheap pickup tool I bought onilne, so I serious doubt it's an ESD dissipative rubber, but they can be bought and when used with a metal tip would create an ESD safe tool.

| 14 gauge vacuum tip with a rubber suction cup attached |

| Suction cup lifting a PCB |

To securely connect the tubing to the hand-piece an ear clamp was used. I'm not sure what the tool was that I used to crimp the lugs. From what I understand, it might be a fencing tool. Edit: I've now learnt they are called pincers.

| Ear clamp with the tool used to crimp the lugs |

I was happy with how things turned out, but the hand-piece needed something more. It was just crying out to be polished. It was rubbed down with 800 grit wet or dry sandpaper. The curved parts were done by cutting strips of sandpaper and wrapping them around the hand-piece. To finish it off it was rubbed down with steel wool and then rubbed with Brasso. There are still a couple of fine scratches that I could get out with a finer grade of sandpaper, but I'm satisfied with the end result.

| After a quick polish |

| After a quick polish |

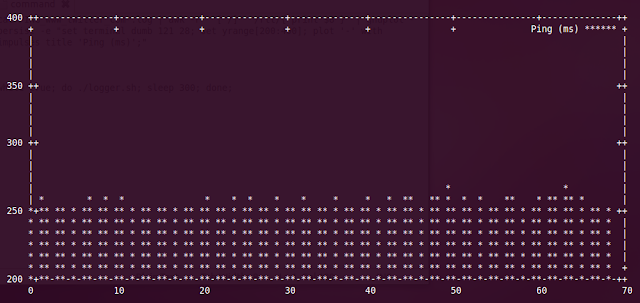

Overall things worked out well, but I still have to tweak the design a little. When the foot switch is released the vacuum isn't released straight away, which means the parts don't come off the vacuum tip for sometimes 40 seconds. Ultimately it means I did too good of a job making sure there were no leaks. I just assumed that the vacuum would release through the pump, but it seals tight when power is removed. Reducing the length of the tubing would also help as it acts as a large vacuum reservoir.

I enjoyed this project. I made something I'm proud of, got to practice silver soldering, and made a tool that's usable and just what I want.